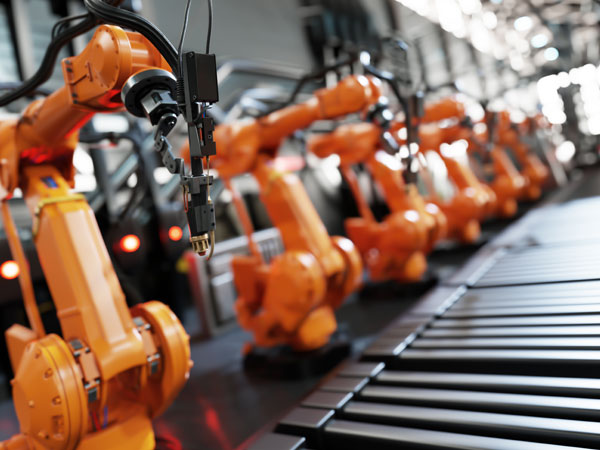

Digitalisierung von Produktion und Intralogistik

Ihr Anbieter für Produktions- und Intralogistiklösungen

Die Anforderungen an die intelligente Vernetzung von Produktionsbetrieben werden immer umfassender. Seit 1988 beschäftigen wir uns mit genau diesen Themen und bieten ein breites Leistungsspektrum im Bereich der Digitalisierungslösungen für die Industrie.

Unser Leistungsspektrum reicht von der Sensorik über die Steuerungstechnik, die Rechnersysteme und Netzwerke bis zu den kompletten Lösungen in den Bereichen Fertigungsleittechnik, Materialflusssysteme, Logistik und MES-Systeme sowie deren Integration in die bestehende Unternehmens-IT.

Egal zu welcher Branche Ihr Industriebetrieb gehört – wir haben die Lösung für Ihre Anforderungen an die Automatisierung der Produktion und Logistik.

Künstliche Intelligenz für OneBase®

Wir sind unglaublich stolz auf die Leistung unseres Teams und freuen uns, dieses beeindruckende ABF-Erfolgsprojekt nun der Öffentlichkeit präsentieren zu können.

ABF GmbH hat bekannt gegeben, dass sie dem Siemens Digital Industries Software Solution Partner Programm beigetreten ist, um die Software Opcenter™ Execution Discrete zu vertreiben.

Seit 2020 ist ABF der Vertriebspartner für Symeo Radarsensoren in Österreich und verwendet die Symeo-Produkte als Integrator seit 15 Jahren erfolgreich in verschiedenen Industriebereichen.

Noch auf der Suche nach der richtigen Produktions- oder Intralogistiklösung?

Bei uns finden Sie die passende Digitalisierungs- und Automatisierungslösung für Ihr Unternehmen.

Sie haben noch Fragen zu unseren Software-Lösungen?